What foundations for your industry 4.0 ?

- your teams are more efficient

- you reduce the non productive delays on all the stages of your production processes

- you trace every single event

- you use your systems to their utmost potential.

What foundations for your industry 4.0 ?

To answer this question, you’ll certainly think of data, AI, cobots or 3D printing. And you will be right !

- your teams are more efficient

- you reduce the non productive delays on all the stages of your production processes

- you trace every single event

- you use your systems to their utmost potential.

Solutions

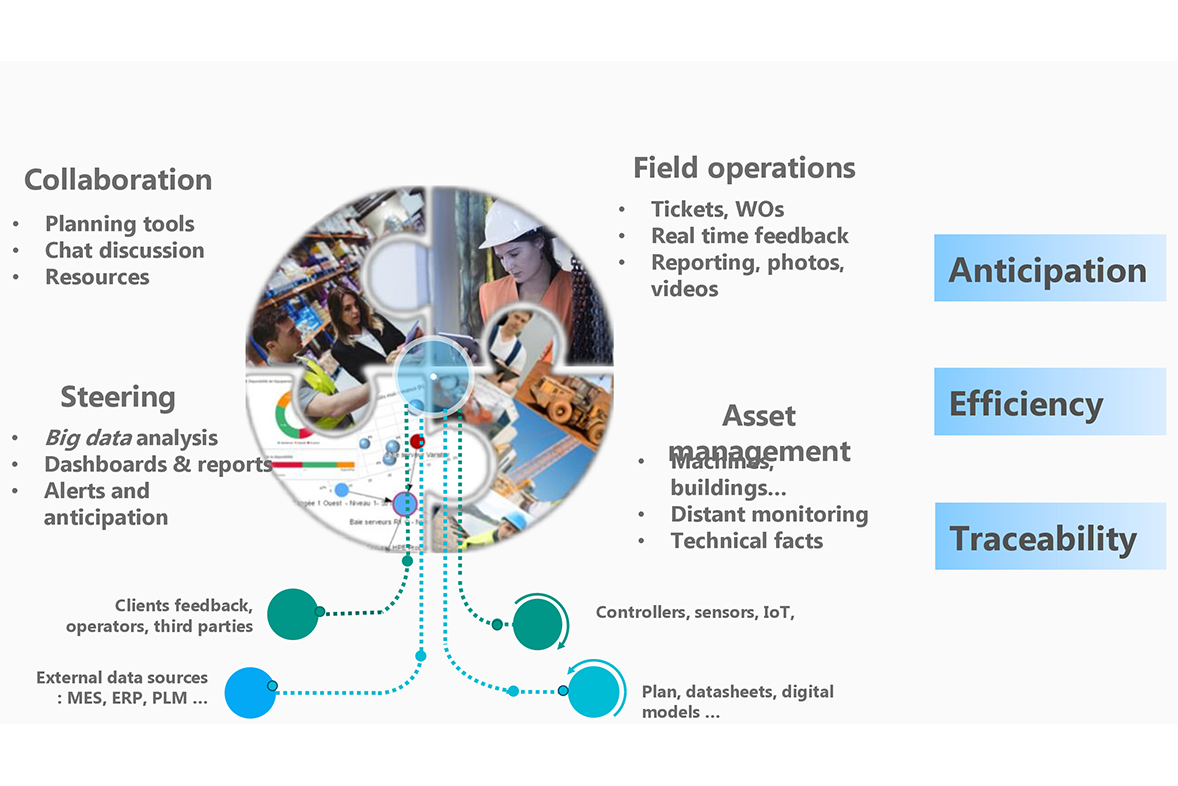

Teams, management, clients, partners, production systems all around the world are more and more connected. They exchange, push, call and handle 24/7 a wealth of data relating to all the company’s operational aspects.

Get the most of it !

The “What is What” is a digital platform designed to facilitate the interaction between all these actors and to turn the exchanged data into actionable information for decision making.

Get the most of it !

The “What is What” is a digital platform designed to facilitate the interaction between all these actors and to turn the exchanged data into actionable information for decision making.

everywhere

operational

IoT

analytics

everywhere

operational

IoT

analytics

Use Cases

Maintenance and field operations

For an “Industry 4.0” organization, no time can be wasted in poorly prepared or inefficiently executed field operations like maintenance. It means that comprehensive, relevant and up-to-date info is available to the in-charge operator (guidance, reference resources, historical records, etc.) and that he can dynamically update the operational picture.

To that end, easy to use and action oriented tools are key.

Decision making and company steering

Accurate, up-to-date and timely available data from all the departments are key for making informed decisions.

No matter how long the top and middle management spend on collecting and processing them, are you sure you always have all you need to know ?

Compliance and traceability

Ability to document all the aspects of the business activity has become critical to the company’s competitiveness and resilience. It’s a matter of compliance with regulations, adhesion to norms and standards, demonstration of performances and -if needed- ability to prove.

The starting point is the capacity of continuously collecting facts, evidences and numbers for immediate or future exploitation which entails continuous consumption of time and energy.

Good news : the automation of this process is possible.

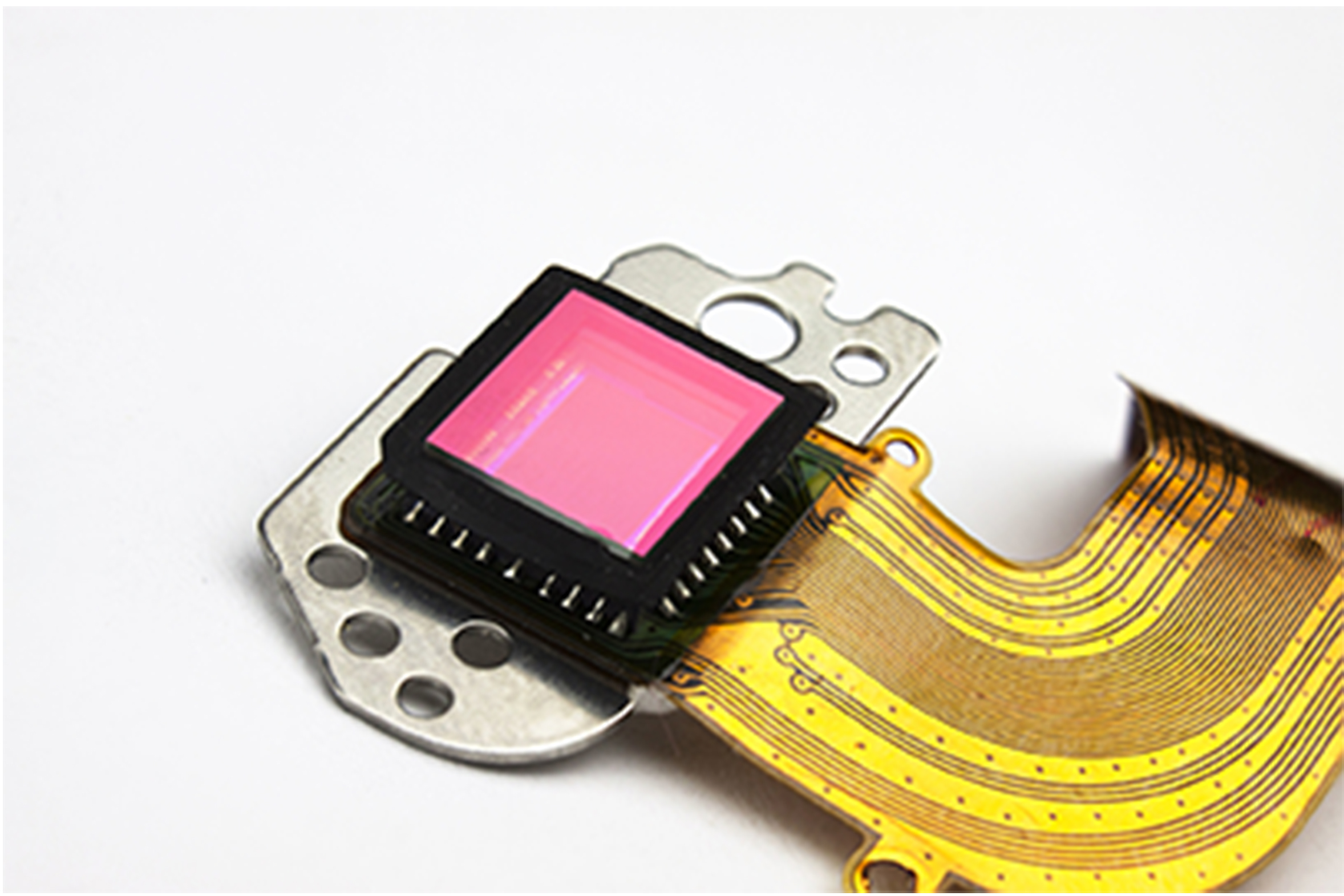

Data analysis for sensors and production systems

After years of research, you’re proud to put on the market this very innovative sensor.

It generates megabytes of invaluable data every second. Such never reached resolution is going to be a game changer for those able to harness the flow of this data. You can sell it “dry” or decide to offer your customers a solution including a software platform for data exploitation.

It will render your product more valuable.

Use Cases

Maintenance and field operations

For an “Industry 4.0” organization, no time can be wasted in poorly prepared or inefficiently executed field operations like maintenance. It means that comprehensive, relevant and up-to-date info is available to the in-charge operator (guidance, reference resources, historical records, etc.) and that he can dynamically update the operational picture.

To that end, easy to use and action oriented tools are key.

Decision making and company steering

Accurate, up-to-date and timely available data from all the departments are key for making informed decisions.

No matter how long the top and middle management spend on collecting and processing them, are you sure you always have all you need to know ?

Compliance and traceability

Ability to document all the aspects of the business activity has become critical to the company’s competitiveness and resilience. It’s a matter of compliance with regulations, adhesion to norms and standards, demonstration of performances and -if needed- ability to prove.

The starting point is the capacity of continuously collecting facts, evidences and numbers for immediate or future exploitation which entails continuous consumption of time and energy.

Good news : the automation of this process is possible.

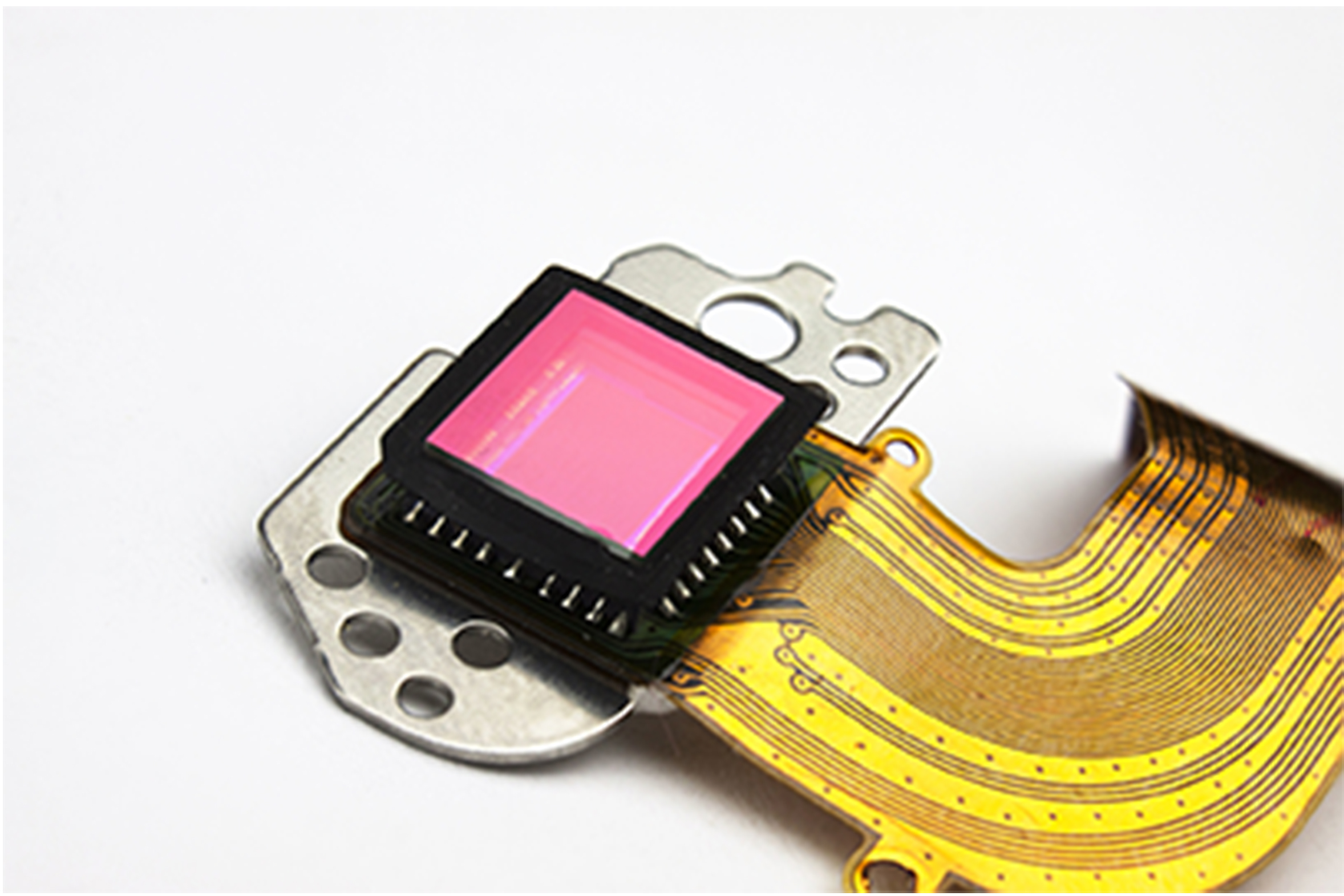

Data analysis for sensors and production systems

After years of research, you’re proud to put on the market this very innovative sensor.

It generates megabytes of invaluable data every second. Such never reached resolution is going to be a game changer for those able to harness the flow of this data. You can sell it “dry” or decide to offer your customers a solution including a software platform for data exploitation.

It will render your product more valuable.

Our Company

The WiW is one of the most innovative software companies in “Grand Est” region, France.

It was created in 2015 to develop a new generation of software solutions for Industry 4.0.

The What is What platform was made available on the market at the end of 2016 after months of R&D.

The WiW is now a 6 people strong company gaining every day more and more acknowledgment as a solution provider.

After initial contracts with businesses in the Grand Est region, The WiW’s solutions are now being used by major companies throughout France.

The WiW is one of the most innovative software companies in “Grand Est” region, France.

It was created in 2015 to develop a new generation of software solutions for Industry 4.0.

The What is What platform was made available on the market at the end of 2016 after months of R&D.

The WiW is now a 6 people strong company gaining every day more and more acknowledgment as a solution provider.

After initial contracts with businesses in the Grand Est region, The WiW’s solutions are now being used by major companies throughout France.

News

Some references